Different Types Of Wood For Furniture Making.

Nowadays, furniture made from wood is quite popular, just like furniture made from other materials because wood furniture gives beautiful, natural wood patterns and colors. It gives a feeling of calm, warmth, relaxation, and comfort to the eyes. It is also suitable for every style of home or room. Even so, the wood used to make furniture is still divided into several types. Let's take a look together and see what types of wood there are? What are the advantages and disadvantages of each type? And is it most suitable for placement or decoration in any type of room?

Getting to know the wood that is commonly used to make furniture

1. Solid wood

Solid wood is wood that is made directly from the trunk of a tree, such as teak, rubber wood, tabaek wood, durian wood, etc. and taken into the process of cutting into various shapes to be compressed into sheets or logs to make dowels that are strong and durable Get a unique wood pattern Popularly used to make general furniture such as beds, sofas, storage cabinets, wardrobes, dining tables, chairs. Suitable for placement in areas that do not get exposed to much water, such as bedrooms, living rooms, offices, hotel or resort halls.

Advantages of Solid wood

- Strong and durable for use

- Can carry a lot of weight

- Beautiful, natural, unique patterns help create a unique look.

- Can be used widely In addition to furniture, it may also be used to make roof frames, beams, battens, fences, door panels, etc.

Disadvantages of Solid wood

- May easily cause scratches and water marks. To solve this problem, a coating of liquid or wax should be applied regularly.

- The wood may shrink or expand. This should allow space to accommodate the installation of furniture.

- There is a risk of being bitten by termites and other insects. But nowadays, real wood that is popular for furniture is coated with insect repellent during the production process. However, over time it may need to be painted or sprayed to prevent insects and termites.

- Relatively heavy difficult to move

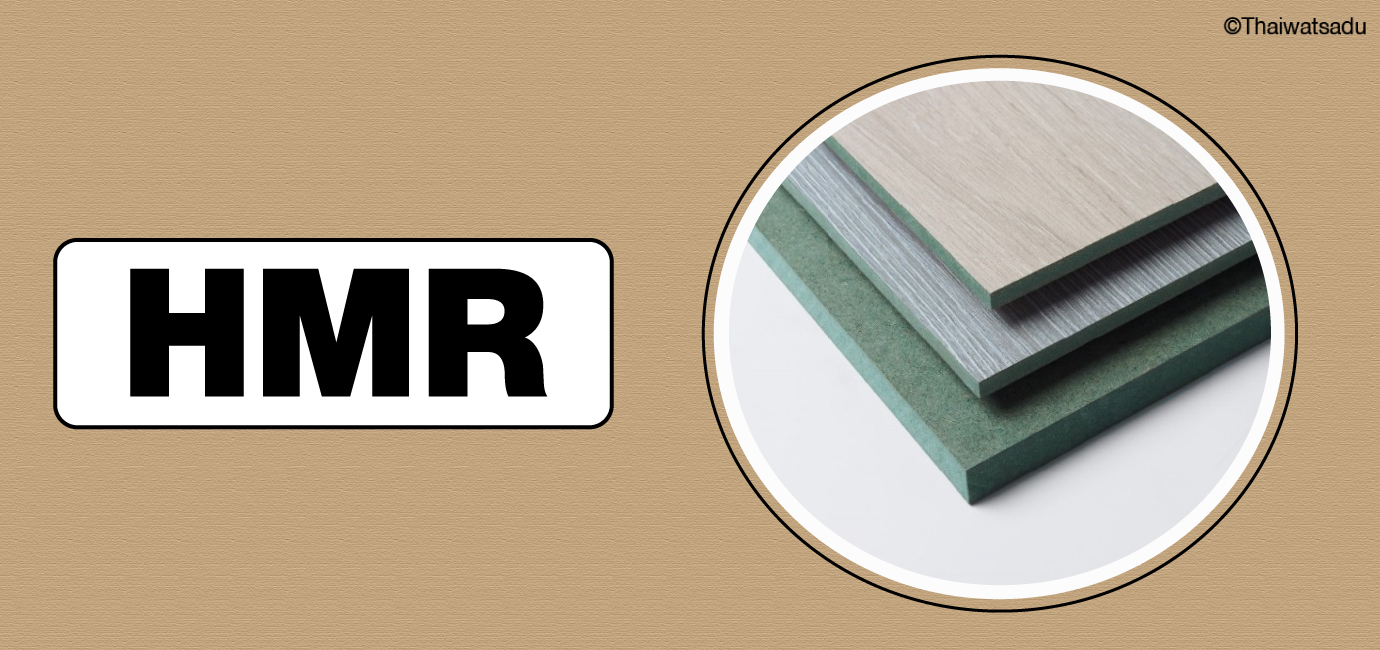

2. HMR wood

HMR wood, an abbreviation for “ High Moisture Resistance board ” is made from eucalyptus wood pieces that are finely ground down to just the fibers and then mixed with moisture-retaining agents and special glues before being put into a press. with high heat Until it becomes a large board that is dark green to light green. Along with taking small pieces of wood to test according to 3 Cyclic Test standards, EN317 standards, 310 standards and 323 standards in order to get the highest quality HMR wood. Most commonly used to make furniture that comes into contact with water from time to time, such as sink cabinets and hanging cabinets in bathrooms in dry zones. Kitchen counter, drop ceiling, decorative wall that can be used in the living room, office or bedroom.

Advantages of HMR wood

- Good humidity resistance

- The wood is firm, durable, strong and can support weight well.

- Can be painted, dyed, and spray painted smoothly.

- Can be bent and punched without breaking the flesh. and the wood is not flaky

- Can be carved and decorated into various beautiful patterns.

- The surface of HMR wood is smooth and consistent throughout.

Disadvantages of HMR wood

- May be more expensive than other types of wood.

- It is heavier than normal wood.

3. MDF wood

MDF wood is an abbreviation of “ Medium Density Fiberboard ” made from scraps of rubber wood. Eucalyptus wood and sawdust that are brought into the grinding process Ready to mix with glue and press with high heat into sheets. Moreover, the exterior surface can be covered with many different materials such as paper, melamine, laminate. In addition, applications are divided according to the density of the wood, including:

- High-density wood type : Mostly used to make house floors, building floors, or to decorate the surface and make wall screens.

- Medium-density wood type : often used in the decorative industry. making furniture Including carvings

- Low-density wood type : Commonly used to make knock-down furniture or self-assembly designs. This will be a piece in which each part will have various holes or dowels around it for you to insert screws. bolt or nut and tighten it.

Advantages of MDF wood

- The wood is dense and strong.

- The surface is fine, smooth and can be painted or spray painted beautifully.

- Can easily be polished to create a rounded surface.

- It is stronger than particleboard.

- Better water resistance than particle board

Disadvantages of MDF

- Unable to support a lot of weight because there may be a deflection However, it has a better weight bearing capacity than particle board.

- When used for cutting, drilling, or turning, it can result in a lot of dust.

- Risk of moths, termites and other insects eroding and destroying the wood. Therefore, it should be painted with termite and insect protection properties as well.

- Does not tolerate moisture Risk of long-term fungal growth

4. Particleboard wood

Particleboard, also known as PB wood, is made from small pieces of wood and sawdust that are pressed together through a process of chemicals, glue, and high-pressure compaction. Until you get wood panels of various sizes. The outer surface is usually covered with melamine printed paper. The wood itself has tough properties but is not as dense as MDF wood. It is commonly used to make general furniture. And suitable for decorating or placing in the living room, bedroom, office or any area that is not exposed to humidity and water.

Advantages of particleboard

- There are various surface covering materials to choose from.

- Easy to clean, just wipe as usual.

- Light weight makes it easy for you to move.

Disadvantages of particleboard

- It is less strong than other types of wood.

- The wood is not dense. There are many air bubbles inside. Makes it unable to support the weight of a lot of things. Risk of bending

- This type of wood cannot be exposed to water. Because it will cause the skin patch to swell. The wood is decaying. Both are at risk of causing mold to occur.

Additional tips for caring for wooden furniture

- Can be cleaned with mild soap and a cloth to wipe the stains on the furniture.

- Do not place wooden furniture in areas exposed to strong sunlight, near bathrooms, or under air conditioners, as this may damage the wood from humidity and heat. There is a risk of mold developing.

- For furniture with grease stains and real wood furniture. Mix vinegar with water in a 2:1 ratio and use a clean, soft cloth to moisten it before wiping the grease-stained area.

- Use a polish to help increase the preservation of wood furniture.

- Avoid cleaning with liquids that contain alcohol or ammonia. Because it can damage the wood, so you should read the label carefully before purchasing.

- Please be careful of being scratched by sharp objects. Whether it's a sharp object from the item used to place it or while assembling Unwrap the wrapping material Because it may damage the wood. The wood pattern is not beautiful.

Shop furniture products online 24 hours a day with Thai Watsadu.

Experience shopping for home products online today with Thai Watsadu, the center for Thai home products. Selling many more furniture that meets every need. Easy to order, convenient, fast, and you can choose to pick up the products at the branch yourself. or choose to receive the product at home Nationwide delivery service Order online at thaiwatsadu.com or contact via Chat & Shop LINE@thaiwatsadu Tel. 1308